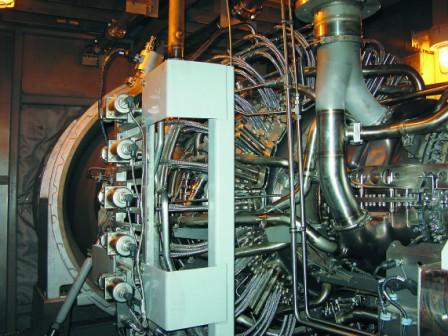

The station with total electric output of 6160 kW will generate electric power for the needs of casing-head gas extraction and utilization. The station consists of four Energo-P1540/6.3KN30power plants each rated at 1540 kW.

The station with total electric output of 6160 kW will generate electric power for the needs of casing-head gas extraction and utilization. The station consists of four Energo-P1540/6.3KN30power plants each rated at 1540 kW.

The plants were developed on the base of Cummins QSV91 gas engines. The customer for the project is Alyansneftegas. NG-Energo delivered main power equipment of the station, carried out construction and commissioning works. Alyansneftegas is the affiliate of Imperial Energy Corp. (Great Britain).

The transportation of the equipment from Genoa sea port to the site of the station was carried out by Natrex Group. The total weight of transported equipment was 3500 tons.Electric output of the station will be 264 MW.

The transportation of the equipment from Genoa sea port to the site of the station was carried out by Natrex Group. The total weight of transported equipment was 3500 tons.Electric output of the station will be 264 MW. The project was realized under the investment program of

The project was realized under the investment program of  The contract for equipment delivery was signed by

The contract for equipment delivery was signed by